Lohmann moulds the future with KW.

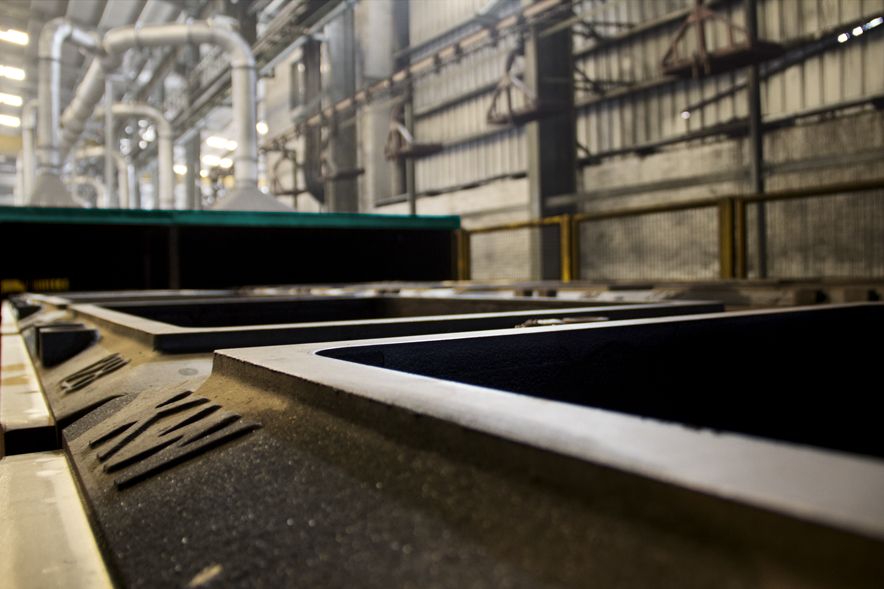

Friedr. Lohmann GmbH of Witten / Germany is a manufacturer of specialty steel and stainless steel products. This family-owned business has attached utmost priority to highest product quality since its very beginnings. Managed by the 7th generation of the family, the company has a proud history spanning more than 220 years. Looking to purchase a new automatic green-sand moulding plant, they regarded only one company as a qualified vendor, a company upholding equally high standards: KÜNKEL WAGNER. The technical specifications for the new plant were truly demanding: frequent pattern changes, frequent changes in alloys cast and, moreover, integration in an existing building.

The LOHMANN project team and KÜNKEL WAGNER’s engineers joined forces to master the challenges presented by the project. The process configuration selected called for moulding, core setting and closing, followed by transfer of the flasks required for casting to a storage and retrieval system in accordance with the quantity of molten metal available for casting – and finally, after completion of the specified cooling time – return transfer to the moulding plant for punch-out of the solidified casting. With the new moulding plant, KÜNKEL WAGNER will be supplying a state-of-the-art solution which fully satisfies LOHMANN’s exacting requirements. The plant, designed to provide a maximum capacity of 24 moulds/h, will be delivered and installed within the year 2015. Both LOHMANN and KÜNKEL WAGNER attach highest importance to innovation, technical expertise and experience in all operations, They have something else in common as well: a long-standing tradition of quality.