Controlled crystallisation, highest casting quality

For your alloys.

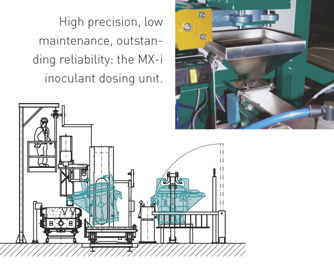

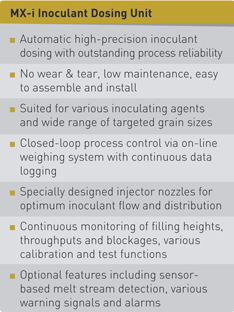

Crystallisation nuclei must be present in the melt stream before and during casting in exact amounts to achieve the desired casting quality. Fully integrated in the process control system, the MX-i inoculant dosing unit performs this crucial task with workhorse dependability.

To control the morphology attained during solidification of the particular alloy processed the inoculation is important. The KÜNKEL WAGNER inoculant dosing unit offers established and time-proven technology for controlled casting morphology.

Highest precision and reliability.

The unit provides precise automated dosing and optimum distribution of any desired inoculants directly into the poured melt stream. Direct addition into the molten metal stream provides highly uniform distribution without fading, therefore maximising the inoculation effect. This improves the metallurgic quality of the casting produced – while reducing usage of costly inoculants. An integrated on-line scale monitors the melt stream for closed-loop correction of the dosage rate in accordance with the selected setpoint. Go with KW – for benefits you won‘t want to do without.

The unit provides precise automated dosing and optimum distribution of any desired inoculants directly into the poured melt stream. Direct addition into the molten metal stream provides highly uniform distribution without fading, therefore maximising the inoculation effect. This improves the metallurgic quality of the casting produced – while reducing usage of costly inoculants. An integrated on-line scale monitors the melt stream for closed-loop correction of the dosage rate in accordance with the selected setpoint. Go with KW – for benefits you won‘t want to do without.