KW rotary mixers

The perfect mix!

Our high-performance batch rotary mixers are cost-efficient. They are the best available in their field and the KEY component in sand preparation plants. And here‘s why:

Rugged construction, clear-cut design. Proven reliability in foundries worldwide.

Rugged construction, clear-cut design. Proven reliability in foundries worldwide.

Our high-performance sand preparation technology has a recipe for success: the mixer.

Our high-performance sand preparation technology has a recipe for success: the mixer.

Not just any mixer. The KW rotary mixer, designed to provide superb performance and rugged reliability in manufacturing practice, day in and day out.

The 250 mixers we have supplied to foundries worldwide over the last 25 years are our best calling cards.

The KÜNKEL WAGNER name stands for expertly processed moulding sand and extensive know-how in pre-mixing, homogenisation, testing and correction of moisture content, final mixing and discharge. When the outlet gate is opened, the compounded moulding sand is ready for use – with optimum flow properties, homogeneity and lump-free consistency.

Discharging the mixer will make you happy. And rightfully so.

When the next mixing cycle begins, KW mixing technology answers the call again, continuing to prove its cost efficiency and reliability in long-term operation. With virtually simultaneous sand infeed and water addition for substantial time savings. With rapid mixing with high-speed impeller tooling. With controlled infeed of additives. With wall-and-floor scrapers ensuring homogeneous mixing and preventing localised dead spots. With high-RPM disagglomeration providing accelerated binder dispersion throughout the blend.

Intensive mixing is a complex process involving continuous rerouting of circumferential sand flow as well as cyclical shear, compression and decompression. In contrast, the results provided by KW mixers are simple: loose, free-flowing sand without lumps. The high standards we set for our mixers are your assurance of optimum performance – day in and day out –at your plant.

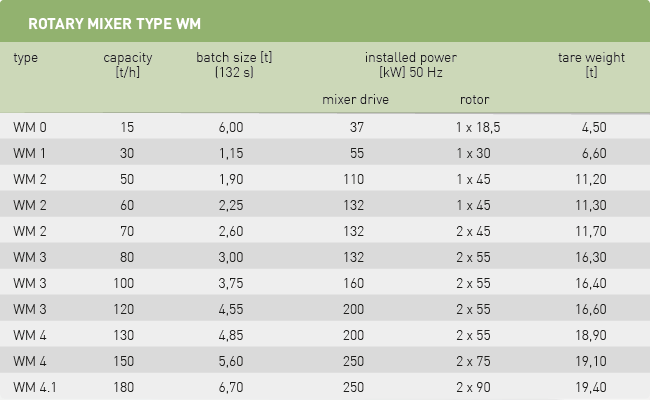

Wide range of equipment available for foundries of all sizes.

Understanding how mixing really works is essential in order to realise the potential in the sand processed. KW knows how to introduce water and additives into used sand – as well as how to deagglomerate bentonite in a way which ensures formation of a uniform bentonite film around every sand particle. KW knows the tools required to do the job: rotating wall/ floor scrapers in conjunction with synchronised high-speed impellers. The more we talk about KW rotary mixers, the clearer things become: the exceptional challenges posed by sand call for exceptional mixing technologies and solutions. Get the best solution for your specific application: contact us by phone or mail.