We quickly mould your needs

When performance is decisive.

The moulding plant that you need must not only meet your current requirements but must also make your production process sustainable.

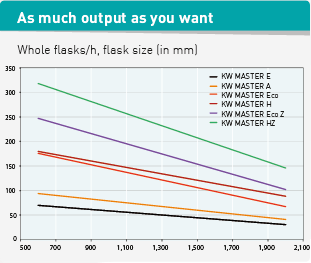

Output is usually defined as work performed per time interval: How many moulds per hour shall the new moulding plant produce and provide for pouring? Which performance is required? Apart from these considerations the required or desired flask size is the first step towards the selection of a suitable single or twin-type moulding machine. To reach the maximum and to be cost-efficient while maintaining the same level of quality.

Our table provides an overview of the performance levels that can be reached by the different machine types depending on their flask size. In addition, the selected mould compaction process will also influence the output.

* The values indicated in the table refer to a simple compaction with the KW multi-piston squeeze head.