Your safety is our concern

Safety first.

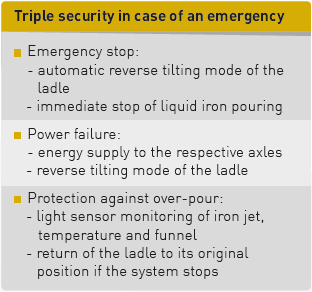

Safety requirements to pouring machines are high. In case of an emergency any hazards can be avoided or reduced to a far reaching extent. Whenever such a situation arises it must be resolved quickly.

A great benefit for your safety: our pouring machines with triple emergency protection.

A great benefit for your safety: our pouring machines with triple emergency protection.

KÜNKEL WAGNER provides a triple protection for the case of an emergency. Our intelligent design includes the use of exchangeable pouring ladles. This benefit extends both to an intended change of the alloy as well as to unintended disturbances and interruptions that might happen in the core shop or in the melting shop.

Changeable pouring ladles: prepared for everything – even for the unprepared.

The suspended ladles are identified by the pouring machine through electromechanical coding. As the ladles are not heated they can be supplied at any time. A maximum deviation of 0,3% between the different castings means a first-rate repeatability from the first to the last casting. This will improve the quality, simplify the planning, reduce the recycle material and save a lot of energy. Positioning of the pouring spout towards the flask pouring gate is ensured in two ways: by laser (defining the position of the pouring machine towards the moulding plant) and by camera – with a view to the pouring gate position.