KW Moulding Machines

Your proper moulding machine.

Experience at KÜNKEL WAGNER is found in every one of our moulding machines. In combination with the moulding plant components conceived to suit the respective application, what emerges is highly productive plant technology specific to the customer: you.

It’s the lessons learnt and ideas that make a product successful.

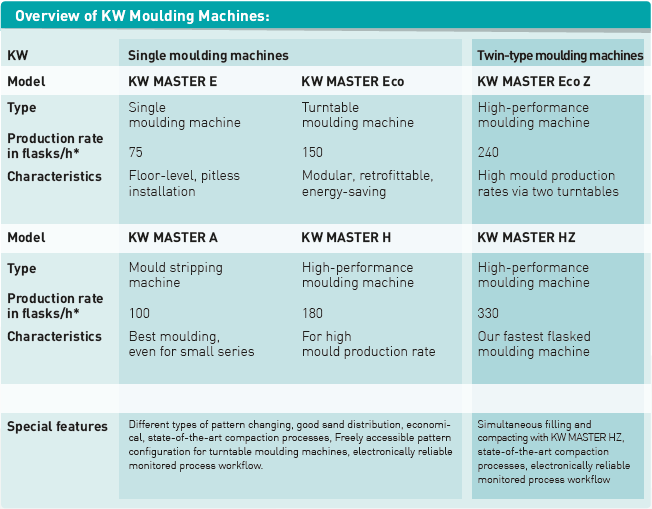

KÜNKEL WAGNER provides different series of single and twin-type moulding machines. Our production program includes precisely what you need. Whether for 20 or 330 moulds per hour, for flaks from 600 x 600 to 3.200 x 1.800 our machines are suitable for your performance requirements and your specific work profile. The machines from each series differ in their working sequences and production output rates. The compaction processes and mould results are not dependent on the type of machine.

The common denominator for all moulding machines from KW is their reliability and functionality, as well as the high mould strength that leads to narrow, achievable tolerances for cast parts, and to optimised weights. The greater expense for a qualitatively superior and technically innovative plant system for light-alloy/iron/steel casting amortises itself in a short time: with the best recommendations.

* for flask format 1,000 x 800 x 300/300 mm