KW Polygonal Screen

Intelligent Screening.

Our patented moulding sand separation process utilise polygonal screens to separate core sand and green sand as soon as possible, ensuring high efficiency.

Know-how at work: KÜNKEL WAGNER polygonal screening units are the most advanced in their category.

Know-how at work: KÜNKEL WAGNER polygonal screening units are the most advanced in their category.

Immediately after removal from the casting, the used moulding sand passes through magnetic separators and is transferred onward for reclamation. The sand then undergoes granulometric processing by the KW polygonal screening unit which breaks up and removes agglomerates. The polygonal screening unit incorporates an innovative geometric design providing maximum physical strength for the rigourous screening process without need for internal supports.

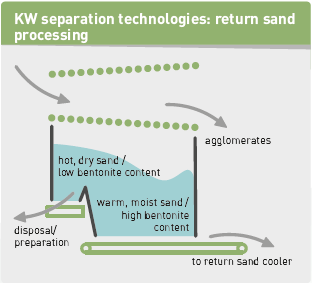

Substantial reductions attainable in additive contents.

The sand in the screening unit is agitated by rotation powered by an externally mounted drive unit. Fine acceptable particles fall through the screen openings whereas coarse particles and lumps are retained and conveyed out. Hot and dry sand is transferred to the sand reconditioning cooler-mixer to be blended with water only and conveyed to storage hoppers whereas moist sand with high bentonite content by-passes the sand cooler. Upgrade the efficiency of your sand preparation process: not a problem – for KW polygonal screening units.