State-of-the-art plants, products and solutions

Sand at its best.

Sand preparation processes must be expertly conceived & conducted to permit reliable, cost-effective and environment-friendly manufacturing. The sand quality achieved depends on the specific processing technologies used.

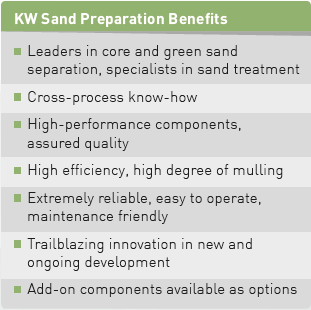

What is the key to successful sand preparation? The right equipment for the job: high-performance sand processing plants from KÜNKEL WAGNER.

Meeting highest standards for moulding sand properties, casting precision and environmental protection.

Foundries of the future benefit from our multifaceted expertise.

We know all interfaces between the casting manufacturing processes, moulding sand and sand preparation processes. We understand how to utilise them effectively to set up fully automated, problem-free operation for years to come.

KW offers a full know-how package in all process sectors required for reliable sand preparation – including sieving, cooling, premixing, storage and homogenisation, in-process checks, mixing, water dosage, storage as well as recycling. KW sand preparation technologies incorporate modular design for adaptability in accordance with the requirements at hand, paving the way for optimum results. Turnkey sand preparation plants are offered as well as individual system components, creating a full range of options for planning ahead. Included are KW process configurations for separation of green sand and core sand, preparation concepts, ideas for saving raw material consumption as well as strategies for quality control, monitoring and

online process data management.