MX 10, MX 20 and MX 30

Clearly better.

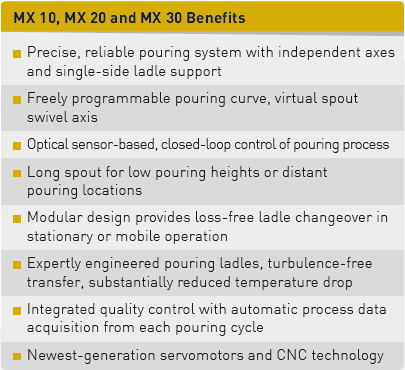

Building pouring machines is something many can do, but replicating KÜNKEL WAGNER‘s expert know-how and experience is quite a different story. So it‘s no surprise that MX pouring machines have held their leading position in the industry for many years. They provide users convincing advantages: performance and superb engineering down to the smallest detail.

Expert know-how, advanced technologies and true passion for metal pouring can be expressed by two letters: KW.

Expert know-how, advanced technologies and true passion for metal pouring can be expressed by two letters: KW.

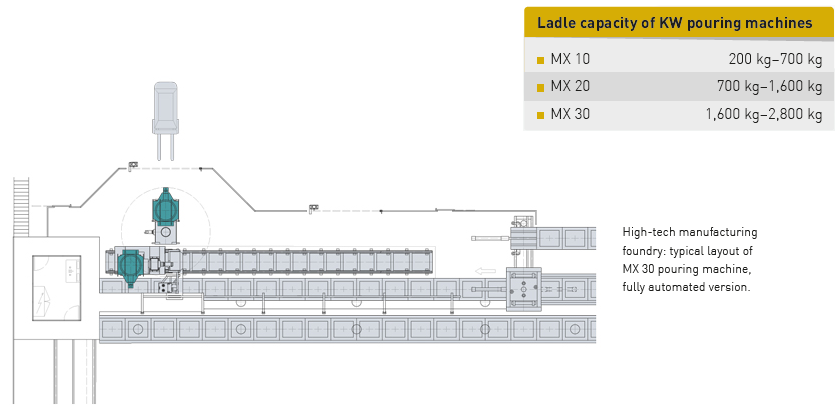

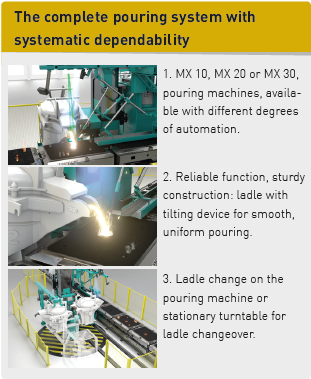

Three times unique: KW pouring machines type MX 10, MX 20 and MX 30. They all provide the outstanding casting quality you expect. And beyond that: they are available with add-on features and components including various degrees of automation creating ideal conditions for precise, loss-free pouring in your specific process.

Innovative features for the next level in pouring machine technology.

Select the right machine with a suitable ladle capacity for your application. And select the degree of automation required, from manual operation over pre-pouring up to our most popular fully automated system which incorporates smart pouring sensors providing weight-defined flow cut-off. An established technology with proven reliability, MAXPOUR systems maximise uptime for highest productivity and profit potential. They radically reduce scrap production, amortising the purchase investment with shortest payback time.

Select the right machine with a suitable ladle capacity for your application. And select the degree of automation required, from manual operation over pre-pouring up to our most popular fully automated system which incorporates smart pouring sensors providing weight-defined flow cut-off. An established technology with proven reliability, MAXPOUR systems maximise uptime for highest productivity and profit potential. They radically reduce scrap production, amortising the purchase investment with shortest payback time.

Dimensions of MX 10: 3,200 x 1,400 x 2,300 mm (LxWxH), MX 20: 4,150 x 1,700 x 3,400 mm (LxWxH),

MX 30: 4,600 x 2,150 x 4,000 mm (LxWxH).