Moulding machine KW MASTER Eco

The perfect combination.

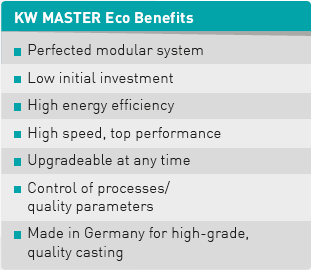

Our “green highlight” for foundries of the future: the modular KW MASTER Eco turntable moulding machine for up to 150 moulds per hour (1000 x 800 mm). The start of a new era in energy savings at moulding plants!

Production is ‘going green’ – in our industry with topics such as resource conservation, environmental impacts and energy efficiency. That’s how the core idea arose at KÜNKEL WAGNER to develop a machine constructed on a modular basis in a unique way. A machine that can be retrofitted, saves energy and delivers high moulding quality with a high degree of efficiency, even in the basic version.

Ingeniously compact modular principle for drastic cost-savings, upgradeable at any time.

With a KW MASTER Eco your investments can be steered intelligently. Instead of having a big production line built all at once, now have a choice at hand on a modular scale: to what extent you develop your plant further, and how far you incorporate directly into your existing plant facilities. The low initial investment allows you sufficient leeway for other plans. As a result KW conforms perfectly to the wishes of many foundries to have a realistic alternative for updating their plant technology. It’s never been easier to opt for achieving your energy efficiency targets without having to give up top performance.

With a KW MASTER Eco your investments can be steered intelligently. Instead of having a big production line built all at once, now have a choice at hand on a modular scale: to what extent you develop your plant further, and how far you incorporate directly into your existing plant facilities. The low initial investment allows you sufficient leeway for other plans. As a result KW conforms perfectly to the wishes of many foundries to have a realistic alternative for updating their plant technology. It’s never been easier to opt for achieving your energy efficiency targets without having to give up top performance.

Experience at KÜNKEL WAGNER is found in every one of our moulding machines. In combination with the moulding plant components conceived to suit the respective application, what emerges is highly productive plant technology specific to the customer: you.