Visionary plant technologies:

Sandmann: KW wins the pitch.

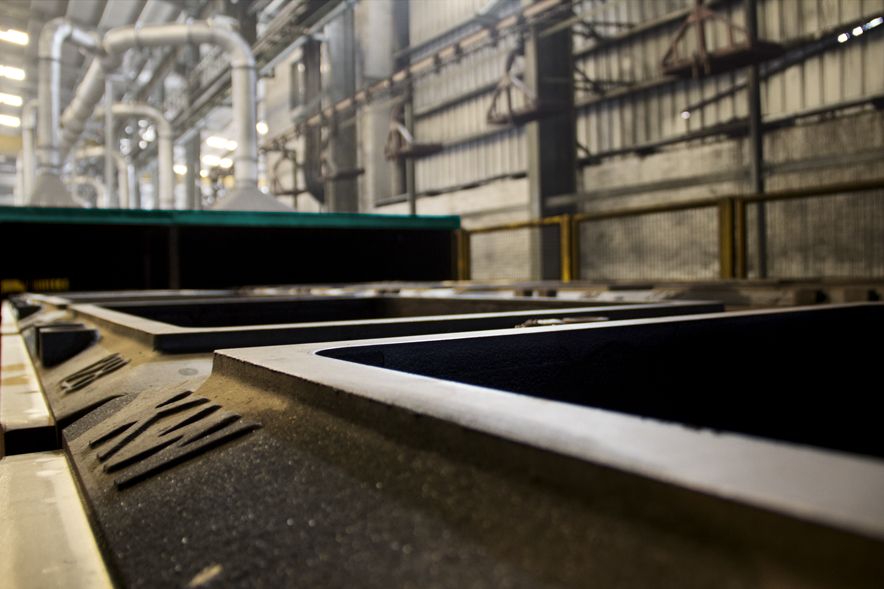

KÜNKEL WAGNER has won the international tender process for a new automatic moulding plant to be manufactured, delivered and installed within the year 2015. The new plant, which will manufacture cast crankshafts and chassis components in nodular and grey cast iron, will be supplied to Messrs. Sandmann Precision Casting of Shanghai / China, a specialised automotive foundry with an excellent reputation for innovative technologies and growth. The KÜNKEL WAGNER moulding plant will accomodate a flask size of 1000 x 800 x 270/270 mm and provide a production capacity of 120 moulds/h. The plant will incorporate state-of-the-art technologies including separate cope and drag core setting lines and four parallel in-flask cooling lines. It will be equipped with the AIRPRESSplus and the TWINPRESS pre-compaction systems.The visionary moulding plant will allow Messrs. SANDMANN to master all future challenges in helping their customers achieve their business goals. “We won out against many competitors. I regard the awarding of the contract to KÜNKEL WAGNER as recognition of the technological expertise of our products and employees”, as proudly stated by Dipl.-Ing. Frank Iburg, Managing Director of KÜNKEL WAGNER. He expects this to send a clear positive signal to further prospective customers looking to benefit from “Made in Germany” technologies